From Raw Materials to Robust Structures – The Journey of Steel Formation in Construction.

What is Steel?

Steel is one of the most important materials in construction and engineering. It plays a vital role in building strong and durable structures. Without steel, modern development would not be possible. In this article, we will explore what steel is, how it is made, the types of steel, and its uses in construction. Let’s know how steel is produced and how can we use steel in construction and why ?

Before understanding steel, we need to know how iron is produced. Iron is made by removing oxygen and other impurities from iron ore. When carbon (less than 2%), manganese (about 1%), and small amounts of silicon, phosphorus, sulphur, and oxygen are added to iron, it becomes steel.

Steel is a versatile material that is stronger and more durable than iron. Steel is widely used in construction and manufacturing because of its strength, flexibility, and recyclability.

The Journey of Steel: From Raw Ore to Modern Infrastructure

Steel, a symbol of strength and resilience, has been the backbone of civilizations for over 4,000 years. Originating in ancient Anatolia and Sri Lanka, the evolution of steel from raw iron to the backbone of modern skyscrapers is a testament to human ingenuity. Today, it is integral to everything from infrastructure to household utensils, contributing to a global industry worth billions. But how is this essential material created? Let’s explore the fascinating journey of steel.

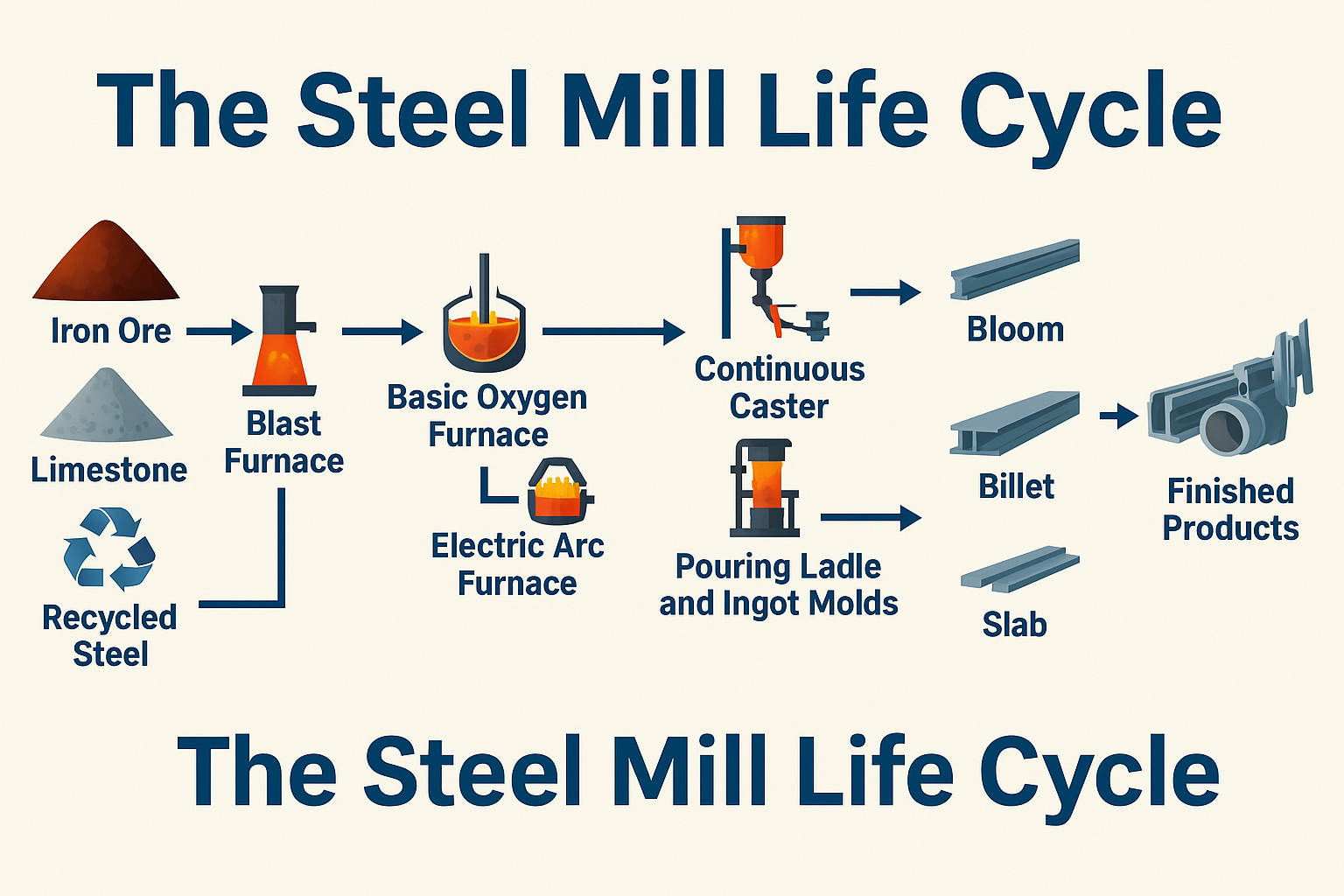

1. Raw Materials: The Building Blocks of Steel

Raw materials like iron ore are never used directly in construction, but steel in construction plays a pivotal role. The journey of steel begins with its primary raw material — iron ore. Extracted through mining operations, iron ore is found abundantly in countries like Australia, Brazil, and China. These reddish-brown rocks are rich in iron oxides and vary in color from dark gray to deep purple and rusty red.

- Iron Ore: Contains iron oxides essential for steel production.

- Coking Coal: A high-carbon fuel sourced mainly from regions like the Appalachian Mountains in the USA and parts of Australia.

- Limestone: A flux material used to remove impurities, widely available globally.

2. Initial Processing: Preparing Raw Materials

Before the steel-making process begins, iron exists underground in the form of powder or dust. It undergoes two processes to become raw material:

- Beneficiation: In this stage, iron dust is separated using a magnetic separator.

- Coking: In this process, coal is heated in a coke oven without air, producing coke – a hard, gray material.

3. The Blast Furnace: Converting Iron Ore to Pig Iron

Steel production takes place in a large blast furnace, which is approximately 30 meters tall. Inside the furnace, iron ore, coke, and limestone are added and heated to over 2000°C to initiate a chemical reaction.

- Coke as Fuel and Reducing Agent: Here, coke acts as both a fuel and a reducing agent, breaking down the iron ore and converting it into molten iron.

- Limestone as Flux: Limestone combines with impurities to form slag, which floats on top of the molten iron.

4. Steel Refining: Reducing Carbon Content

The molten iron, known as pig iron, contains high carbon levels, making it brittle. To refine it into usable steel, it is transferred to either a Basic Oxygen Furnace (BOF) or an Electric Arc Furnace (EAF):

- BOF Method: Pure oxygen is injected into the furnace to reduce carbon content, creating carbon monoxide and dioxide.

- EAF Method: Scrap steel is melted using electric arcs, ideal for recycling steel and controlling impurities.

5. Alloying and Ladle Refining: Fine-Tuning Steel Composition

At this stage, alloys like manganese, nickel, and chromium are added to achieve desired properties such as strength, hardness, and corrosion resistance.

- Ladle Refining: This stage involves deoxidation and desulfurization to remove residual elements and maintain the steel’s integrity.

- Temperature Control: The steel is maintained at approximately 1,650°C to ensure consistency and optimal alloy mixing.

6. Casting: Shaping the Steel

The molten steel is then cast into semi-finished forms:

- Continuous Casting: Steel is poured into water-cooled molds, forming slabs, blooms, or billets.

- Ingot Casting: Steel is poured into large molds and later reheated and rolled into shapes.

7. Primary Forming: Hot and Cold Rolling

After casting, steel undergoes rolling processes to shape it into sheets, rods, bars, or plates:

- Hot Rolling: Steel is heated and passed through large rollers to refine its shape.

- Cold Rolling: Further rolling at room temperature for tighter tolerances and smoother finishes.

- Annealing: A heat treatment to reduce brittleness and improve ductility.

8. Coating and Finishing

Steel products often receive protective coatings based on their intended use. This is final stage of steel making process:

- Galvanizing: A zinc coating to prevent corrosion.

- Tin Plating: Applied to steel used in food packaging.

- Color Coating: Enhances the aesthetic appeal of construction materials.

9. Quality Control: Ensuring Consistency and Durability

Throughout the manufacturing process, quality control is essential to ensure the steel meets industry standards:

- Testing: Tensile, hardness, and microscopic analysis.

- Non-Destructive Testing: Ultrasonic and radiographic testing to detect internal flaws.

10. Environmental Considerations: Sustainability in Steel Production

Modern steel plants implement various eco-friendly measures to reduce their environmental footprint:

- Dust Collection Systems: Minimize air pollution.

- Wastewater Treatment: Prevents contamination.

- Energy Efficiency: Incorporating energy-saving technologies.

11. Packaging and Distribution

Once the steel passes final inspections, it is bundled and labeled with tracking information for transportation. Additional protective layers, like waterproof paper or plastic wraps, may be applied to prevent corrosion during transit. After this, different items are made from steel, which are used in construction under various brand names.

Types of Steel

Steel in construction is not a single product but a combination of various alloys. There are over 3,400 types of steel, each with unique physical, chemical, and environmental properties. Modern steel is being developed to be lighter yet stronger, reducing the amount of steel used in construction while maintaining its structural integrity.

Read more about types of steel & grades

Major Steel Companies in India

India hosts over 134 steel companies, but when it comes to steel in construction, a few top players dominate the market. Tata Steel stands out with a diverse range of steel brands specifically designed for construction and other sectors. Here are the top 10 steel companies shaping the construction landscape in India:

- Tata Steel Limited

- Steel Authority of India Limited (SAIL)

- JSW Steel Limited

- ArcelorMittal Nippon Steel India

- Jindal Steel and Power Limited (JSPL)

- Vedanta Limited (ESL Steel)

- Rashtriya Ispat Nigam Limited (RINL)

- VISA Steel Limited

- Godawari Power and Ispat Limited

- NMDC Limited

Major Steel Cities in India

Steel production is concentrated in several states and cities in India:

- Jamshedpur (Jharkhand): Tata Steel

- Bokaro (Jharkhand): SAIL, Vedanta

- Rourkela (Odisha): SAIL

- Angul (Odisha): JSPL

- Durgapur and Burnpur (West Bengal): SAIL, IISCO

- Bhilai (Chhattisgarh): SAIL

- Vizag (Andhra Pradesh): RINL

- Vijayanagar (Karnataka): JSW Steel

- Salem (Tamil Nadu): SAIL, JSW Steel

- Hazira in Surat (Gujarat): AM/NS India Ltd.

- Dolvi and Vasind (Maharashtra): JSW Steel

Properties of Steel

Steel in construction is renowned for its exceptional strength, durability, and flexibility, making it a preferred choice for building large structures, industrial complexes, and infrastructure projects. Additionally, it is recyclable, fire-resistant, and incredibly difficult to break, further solidifying its reputation as an ideal material in modern construction practices.

Types of Steel in Construction

- Structural Steel: Used for beams, columns, and frameworks.

- Reinforcement Steel (Rebar): Strengthens concrete structures.

- Steel Pipes and Hollow Sections: Used in construction and industrial applications.

- Cold-Formed Steel: Used in lightweight framing systems.

- Specialty Steels: Includes weathering steel, stainless steel, and high-strength, low-alloy (HSLA) steel.

Applications of Steel in Construction

- Residential Buildings: Used in modern homes and multi-family residences.

- Commercial and Industrial Buildings: Applied in office complexes, warehouses, and factories.

- Infrastructure Projects: Bridges, tunnels, airports, and other infrastructure.

- Prefabrication and Modular Construction: Speeds up construction while reducing waste.

Advantages of Using Steel in Construction

- Cost-Effectiveness: Steel is durable and low-maintenance, reducing long-term costs.

- Speed of Construction: Prefabrication and modular designs save time.

- Design Flexibility: Allows for innovative designs without internal columns.

- Sustainability: Steel is recyclable and has a lower environmental impact than other materials.

Challenges and Considerations

- Corrosion and Rust: Can be managed with coatings and treatments.

- Thermal Conductivity: Proper insulation is needed to manage heat transfer.

- Fire Resistance: Fireproofing measures are essential for steel structures.

Conclusion

The journey of steel from raw ore to an important industrial material is an example of human ingenuity and technological progress. From old traditional methods to modern, precise processes, steel remains a foundational element in infrastructure, vehicles, appliances and other manufacturing machinery & equipment. If new innovations in steel continue to emerge and people start using it for development, we will achieve significant progress in the coming times.

2 thoughts on “Steel in Construction – From Molten Metal to Skyscrapers”