It is difficult to imagine the modern world without steel – from infrastructure to appliances, steel is everywhere and in every shape. Here we will discuss on steel grades & its types.

Steel is the backbone of Modern World

Steel – This is a material that is seen everywhere around us. Infrastructure, cars, trains, ships, machines, production lines, cranes, appliances, elevators, kitchens, tech devices, spaceships, airplanes – almost everything is made of steel. Steel is one of the most used engineering materials in the world. We cannot imagine today’s modern world without steel.

But all steels are not the same. There are different steel grades and each one has its own specific purpose. Some steels are designed for structural work – they provide good weldability, are ductile and are cost economical.

Some steels are designed to withstand heavy loads and impact. Some are designed to carry bearing loads. Some steels are designed for spring function. And some steels are designed to have an aesthetically appealing – shiny finish that can resist rust for decades.

For a mechanical design engineer choosing the right steel grade is very important. But the challenge is that there are around 300-500 unique types of steel grades defined and these fall under 6-7 international standards. These international standards are country-wise or industry-wise. Like:

- In USA AISI/SAE standard is followed for automobile and manufacturing, and ASTM for construction

- EN ISO is common in Europe

- JIS standard in Japan

- BIS (Bureau of Indian Standards) standard in India

But there is another problem in India – at ground level most of the steels in market are not labelled as per IS standards. Like, plain carbon steel is sold in market as ‘MS’ (Mild Steel) – without mentioning specific grade. On the other hand, stainless steel and tool steel are mostly labelled under AISI standard like 316, 304, D2, D3.

This confusion occurs because in India the old British EN standards are still popular – like EN19, EN24, EN31. These grades are technically obsolete but people in the industry understand them and hence they are still used today.

Manufacturing Process of Steel

To make steel, iron ore is first refined. Iron ore is crushed to make a fine powder and then impurities are removed from it. This refined iron is melted in a blast furnace with coke and limestone. This gives molten iron which is called ‘Pig Iron’.

Pig iron has high carbon content (4-5%), which has to be reduced to make steel. Its next step is

BOF (Basic Oxygen Furnace) where carbon content is reduced by blowing oxygen. After that, if alloy steel is to be made then elements like magnesium, chromium, nickel, vanadium are added.

To learn more about steel & manufacturing process read Steel in Construction – From Molten Metal to Skyscrapers

Know more about Tata Steel’s Steel making process https://www.tatasteelnederland.com/en/How-we-make-steel/process-of-steelmaking

Steel Grades and Standards

Steel grades are defined according to different standards. Such as:

- AISI/SAE: Common in USA and automotive industry.

- ASTM: For construction and piping industry.

- EN ISO: For Europe and global exports.

- JIS: Used in Japan and Asia.

- BIS: For Indian government tenders.

- DIN: In Germany and some machine shops.

Each standard has its own nomenclature. For example, AISI 304 stainless steel is popular in the USA. The same steel is sold as SUS304 in Japan and as X5CrNi 1810 in Europe.

Steel Grade Chart

| Standard | Grade | Composition | Application |

|---|---|---|---|

| AISI | 1018 | Low carbon steel | Shafts, spindles, pins |

| AISI | 304 | Stainless steel, 18% Cr, 8% Ni | Kitchen equipment, pipes |

| ASTM | A36 | Carbon steel | Structural shapes |

| EN | S235JR | Carbon steel, low strength | Construction structures |

| JIS | SUS304 | Equivalent to AISI 304 | Food processing equipment |

| BIS | IS 2062 | Mild steel | General structural purposes |

| DIN | C45 | Medium carbon steel | Gears, axles |

| AISI | 4140 | Alloy steel, Cr-Mo | Heavy machinery components |

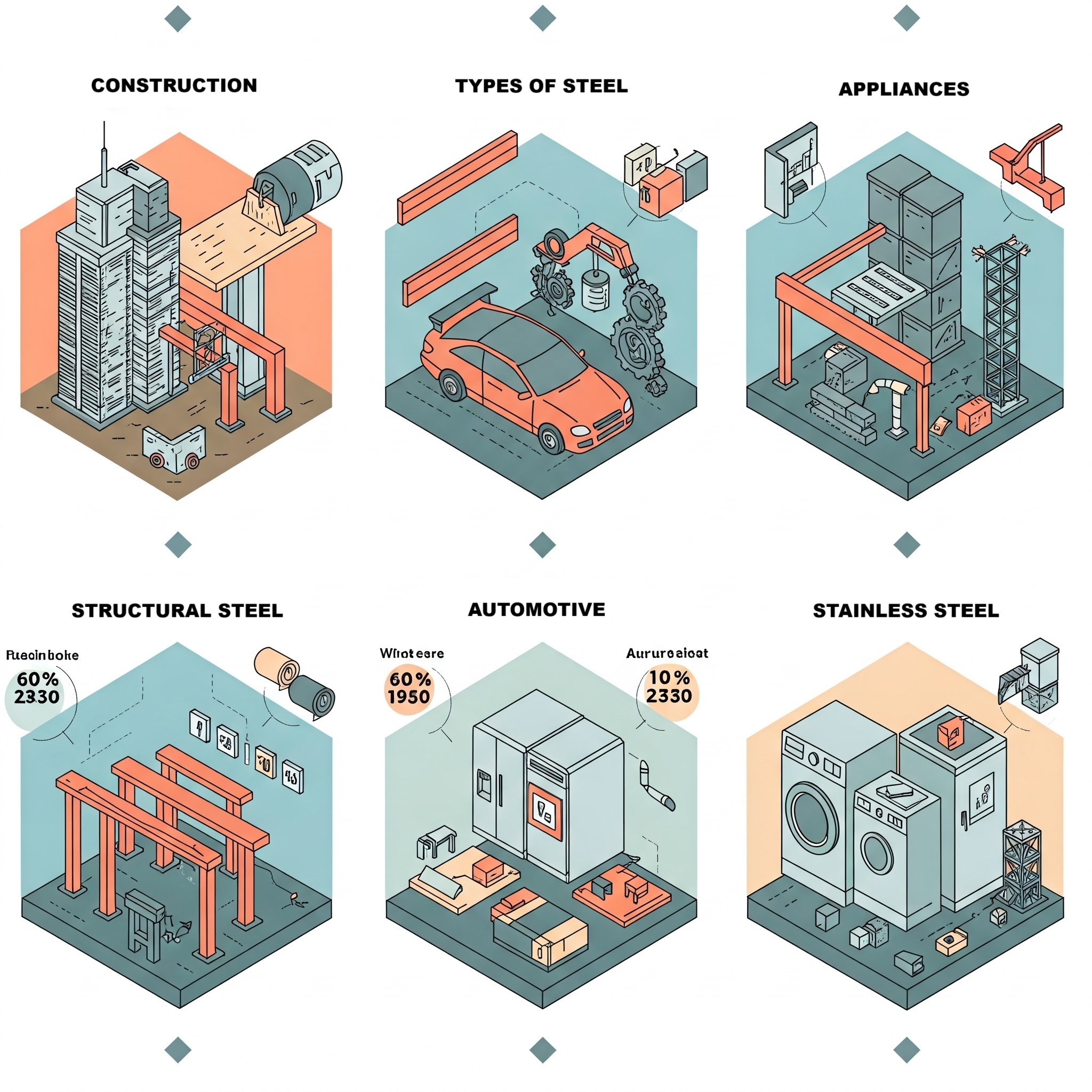

Types of Steel

Steel is broadly divided into 4 main categories:

- Carbon Steel: Basic and economical, which is a mixture of just iron and carbon. Its types are low, medium, and high carbon steel.

- Alloy Steel: Elements like magnesium, chromium, and vanadium are added to it for added strength and toughness.

- Stainless Steel: It contains more than 12% chromium, which makes it corrosion-resistant.

- Tool Steel: It is made for high hardness and wear resistance. It contains elements like tungsten and molybdenum.

Final Thoughts

Steel is the most widely used material in the world and it has different grades and standards. It is critical for an engineer to choose the right steel grade. If you know the name of one grade, you can easily find its equivalent in another standard. In this way we can make projects more durable, cost-effective and safe by selecting the proper steel.

1 thought on “4 Steel Grades Exposed: Why Some Shine & Others Fail!”